A research team led by Prof. Zhang Dun from the Institute of Oceanology of the Chinese Academy of Sciences (IOCAS) has developed a novel in-situ growth, bismuth oxyiodide (BiOI) film on a 3D-printed polymer substrate through successive ion layer adsorption reaction (SILAR) for water purification. The study was published in Separation and Purification Technology on May 4.

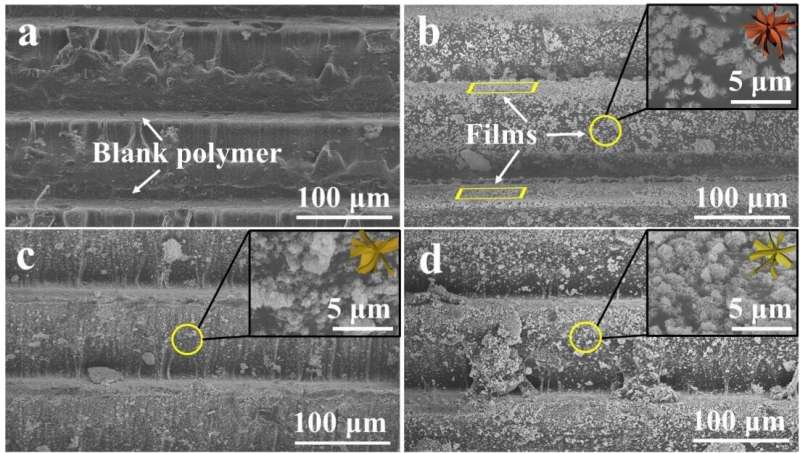

The researchers found that the substrate was completely covered with floriform microstructure film. They introduced OH–/I substitution strategy to fabricate iodine-defects engineering BiOI film. The superficial color of the 3D-printed substrates ordinally changed from gloss white to brownish yellow, dark yellow, and light yellow, which was ascribed to the change of band gap caused by iodine-defect engineering film.

During the growing process of films, iodine spaces were introduced into the BiOI crystals, increasing BiOI internal electric field and electron density and improving photoinduced carrier separation and transmission efficiency. Iodine-defects engineering BiOI exhibited smaller grain size, higher specific surface area, electronegativity, photoelectric response and photocatalytic activity than stoichiometry BiOI.

The researchers proposed that Bi3+ firstly adsorbed on polymers to construct the active grown sites of the film. With the extension of time, the films gradually self-assembled into petal-like BiOI film. High proportion and movement speed of I– promoted the in-situ growth of BiOI film along the crystal plane.

“The film exhibits good photocatalytic activity and cyclic stability on photodegrading organic compounds and sterilizing microorganism,” said Xu Xuelei, first author of the study.

More information:

Xuelei Xu et al, In-situ growth pH-adjusted iodine defects engineering BiOI film on 3D-printed polymer substrate for efficient organic pollutant and microorganism purification, Separation and Purification Technology (2023). DOI: 10.1016/j.seppur.2023.123974

Citation:

3D-printed polymer substrate coated with photocatalytic film developed for efficient water purification (2023, May 11)

retrieved 11 May 2023

from https://phys.org/news/2023-05-3d-printed-polymer-substrate-coated-photocatalytic.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.

Denial of responsibility! TechCodex is an automatic aggregator of the all world’s media. In each content, the hyperlink to the primary source is specified. All trademarks belong to their rightful owners, and all materials to their authors. For any complaint, please reach us at – [email protected]. We will take necessory action within 24 hours.

Jessica Irvine is a tech enthusiast specializing in gadgets. From smart home devices to cutting-edge electronics, Jessica explores the world of consumer tech, offering readers comprehensive reviews, hands-on experiences, and expert insights into the coolest and most innovative gadgets on the market.