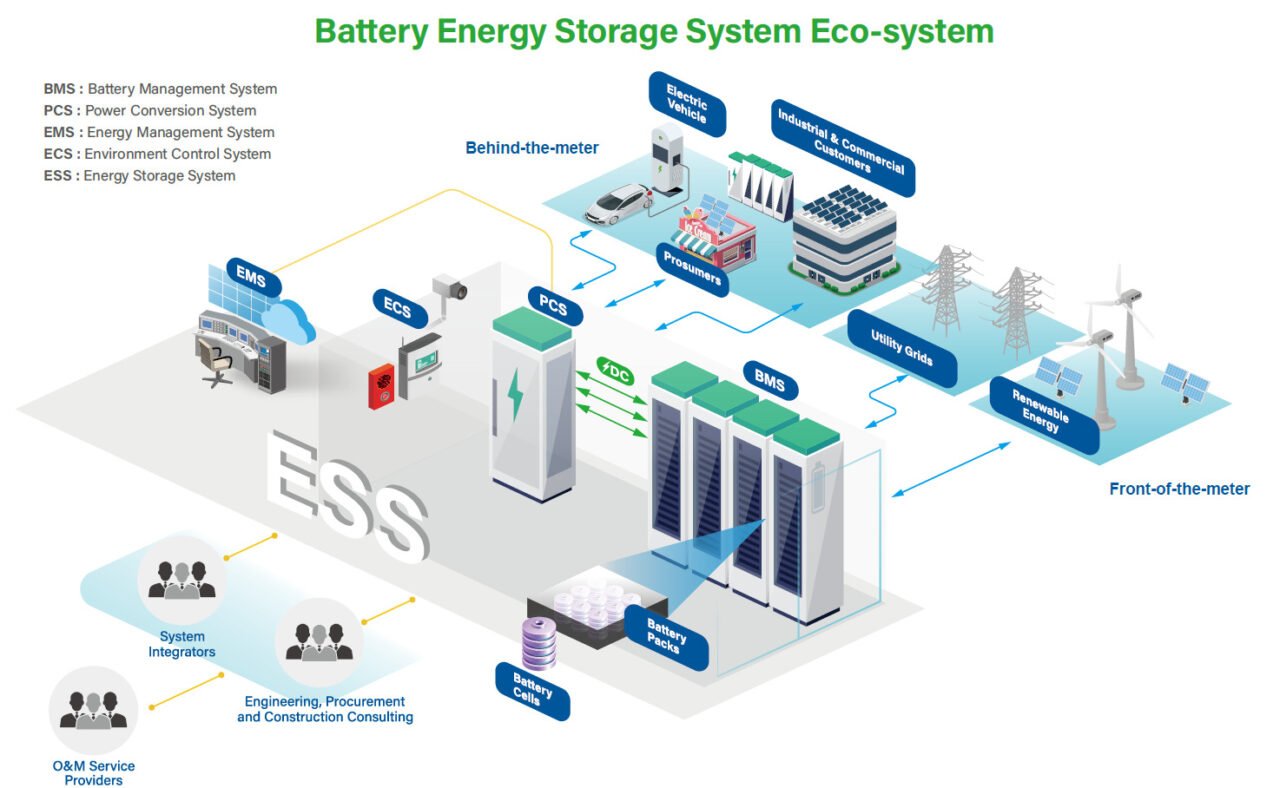

Through this integration process, it becomes possible to optimise BESS operations and communications with real-time monitoring and control. In short, application-specific IoT solutions for BESS can help facilitate the energy industry’s transition towards a successful future driven by digitalisation, decentralisation, democratisation and decarbonisation, catering to both front-of-meter and behind-meter prosumers.

Green energy trends and opportunities

Grid digitalisation means establishing energy storage solutions that can support the integration of renewable energy into smart, flexible power systems. The effects of digitalisation will have an impact on the whole process, from generation and storage, to transmission, distribution and consumption. If businesses want to take control of energy demands on both sides of the meter, they will need to deploy energy systems capable of real-time AI.

Another trend/opportunity is decentralisation, which is becoming critical for any systems that need to demonstrate energy security. Decentralisation will necessitate a major contribution from businesses, especially larger enterprises, in the adoption of self-generation solutions. These solutions will permit businesses to manage their own energy requirements through the construction of micro grids.

Aligned to decentralisation, energy democratisation will continue to engage public effort in the transition to renewable energy. The enablement of independent energy producers and energy trading will result in better guidance for the entire sector. The industry will also become more responsive, driven by policies and decisions made on the basis of local requirements.

In tandem, advancements in decarbonisation will require the re-evaluation of business objectives by exploring viable sustainability pathways and alternative financing options in order to cut emissions. A key consideration will be partnering with suppliers that can help deliver energy efficiency targets via the deployment, operation and management of renewable energy systems.

The challenges

When it comes to IoT integration for a BESS installation, businesses must navigate many challenges, not least system cost, scalability, connectivity, network security and remote device management.

BESS cost is always a primary concern, and when implementing an IoT-based BESS, users need to consider costs that include hardware, software, installation and maintenance to reach an estimate of TCO (total cost of ownership). After all, if the system is not profitable, the business model is not sustainable. Simplifying design and maximising system efficiency are key elements of driving profitability.

Future scalability also comes into the equation regarding both system success and cost. A scalable BESS is essential for future growth and development. By partnering with a technology supplier which can offer a complete IoT product portfolio, users are able to build a scalable IoT infrastructure for their BESS, within budget.

A well-connected BESS also needs to utilise reliable and secure communication infrastructure, as well as robust computing power that can work autonomously. Connectivity is necessary in both the sensing and network layers – the latter aggregates data from the various IP devices present in the system.

During integration, most projects will encounter a multitude of different connectivity interfaces, including serial, one-wire, CAN bus, digital input, analogue I/O, Ethernet and fibre. Connectivity might sound like a simple plug and play exercise, but it involves lots of interface integration to achieve reliable data transmission pathways. Here, the latest IoT sensing, computing and communication products enable users to create a well-connected system for their BESS without concerns about system integration.

As a further point, it is necessary to embed network security in multiple layers at each connection point to thwart potential threats. A VPN, firewall and data encryption are among the crucial tools of effective system security

Similarly, whether the BESS is operating on a grid scale or commercial scale, it requires remote device management to ensure overall grid stability and robust power capacity. Remote device management is also very useful for BESS troubleshooting, system health monitoring and the implementation of predictive maintenance strategies that help maximise asset uptime.

A proven IoT device management service can connect and manage all IoT devices, whether on a public cloud or on-premise instance. The selection process should take account of easy integration with third-party platforms via open standards, such as OpenAPI, for seamless remote data and device management.

Data, data and more data

All of these objectives, challenges and opportunities require the same thing to succeed: data, and lots of it. To help achieve the optimal system solution, there is a need to achieve real-time data communications, or as close to it as possible. Only this way will energy grid operators and producers be able to deliver a sustainable, stable and resilient power supply into the rapidly and ever-changing energy ecosystem of the future.

The energy industry has seen heavy investment in renewable sources for many years now; from wind and wave to solar and green hydrogen. Everyone knows that the output of these technologies is highly variable depending on weather conditions. The ability to store the energy produced for various purposes – including power quality, stability and peak demand response – therefore becomes essential

To complete this ecosystem of sustainability, energy storage is critical, necessitating the deployment of BESS in both grid-scale, front-of-the-meter (FTM) and commercial-scale, behind-the-meter (BTM) applications.

FTM installations, a rapidly expanding area where much of the growth in demand for BESS is coming from renewable developers using short-term storage to address intermittency issues, are typically larger than 10MWh.

BTM installations range from 10MWh down to 30kWh in capacity and fall into four broad categories: as well as public buildings, factories and offices, BESS is being adopted in electric vehicle charging infrastructure, as backup supply for critical infrastructure, and as a replacement for petrol and diesel generators.

Whatever the scale, integrating an IoT solution which combines sensing, communication and computing technologies can help to build a sustainable BESS installation that is reliable and flexible.

Certain technology providers are spearheading the development of hardware and software that can facilitate the roll-out of integrated renewable energy/BESS solutions. This capability includes the collection of analogue data in solar arrays and wind turbines, as well as in battery management systems (BMS).

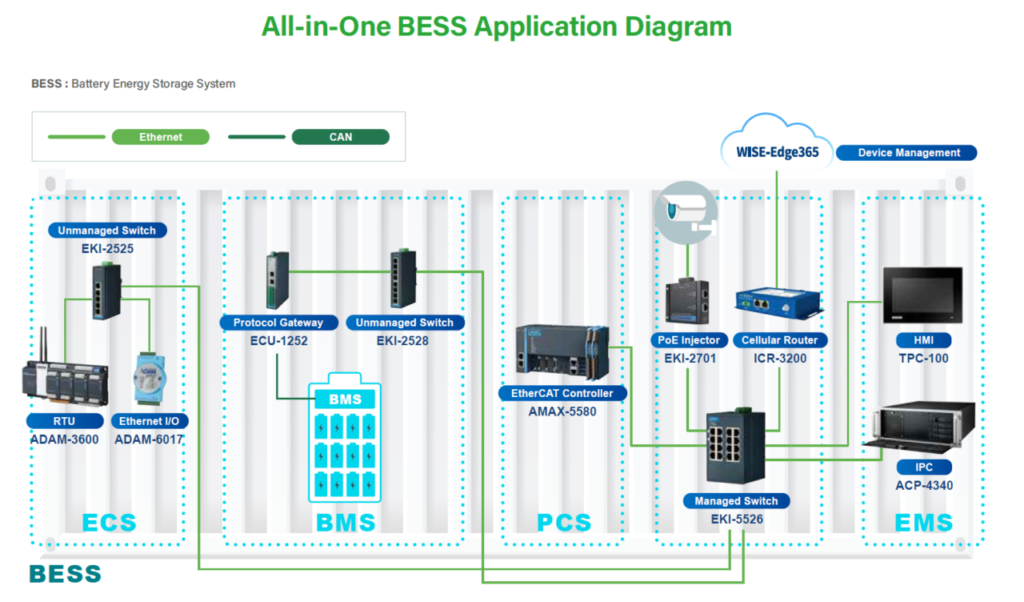

The BMS is responsible for the real-time monitoring and load control of each battery cell. A BMS typically uses a CAN bus for external communication, with a communication gateway required to convert CAN bus data to Ethernet data. Selecting the right gateway will ensure seamless data transmission and power dispatch to utility grids.

It is also necessary to collect data from the power conversion system (PCS), which serves as the core of electricity scheduling and dispatch because it converts AC and DC power with a focus on real-time control via EtherCAT.

Energy storage systems (ESS) and environmental control systems (ECS), which combine the fire and HVAC system, are further data collection targets. This activity even extends to applications in the overall energy management system (EMS), providing a seamless and highly effective offering.

The EMS typically includes SCADA software and industrial PCs (IPCs) working together to provide overall monitoring of the energy storage container. Usually, two sets of IPCs provide back-ups of each other for SCADA stability, while a further two sets provide back-ups of each other for database redundancy.

Deep product stacks

The latest deep product stacks (both hardware and software) can address the specific needs of key applications, helping to build the ideal solution.

Firstly, taking a holistic approach, one of the key challenges is connecting to devices with both Ethernet and CAN bus across all of the potential applications within a BESS, regardless of their location to the meter. Data requires seamless transfer between BESS functions and applications to maximise performance and efficiency.

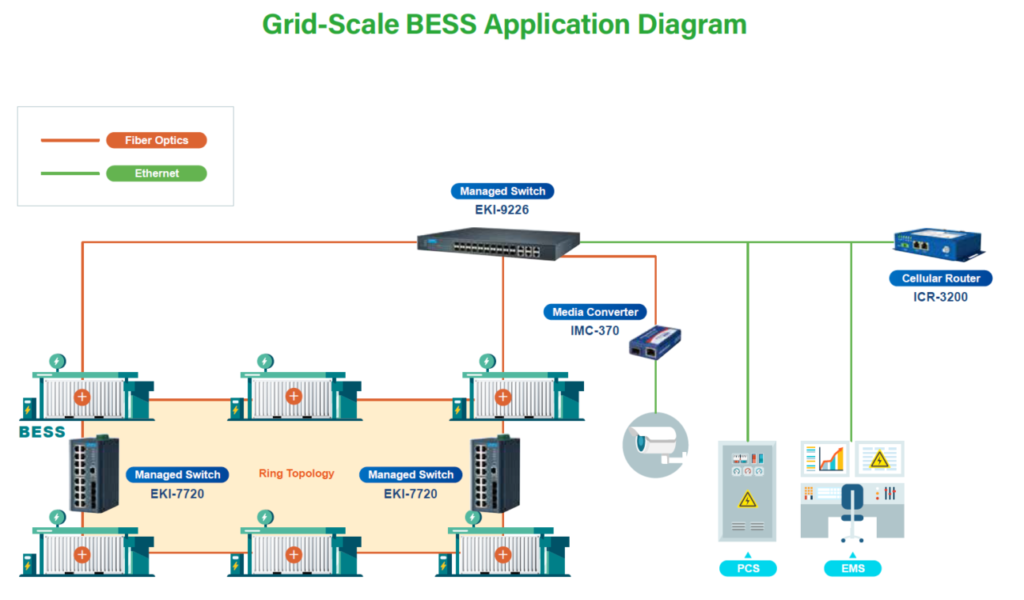

Optimal component selection becomes paramount to project success in applications such as grid-scale BESS (where technologies connected to the power grid can store energy and supply it back to the grid at a more advantageous time) and higher level installation architecture. Such components include Ethernet switches, with both copper and fibre interfaces.

In the large grid-scale energy storage field, the BMS, PCS and EMS function in different containers, and each container must maintain data communication at all times to manage charging and discharging. The containers connect using fibre-optic ring topology to enhance network redundancy and ensure the highest stability.

By leveraging the latest managed Ethernet switch technology, it becomes possible to connect each BMS and transmit Ethernet signals over fibre-optic cables. This ensures seamless data exchange between distributed BMS containers. On the ring network’s top layer, it is advisable to use IEC-61850-3-certified managed Ethernet switches to connect PCS, EMS and multiple BMS containers.

Another core component is the media converter. Since security management of the energy storage system is critical, an industrial gigabit Ethernet-to-fibre media converter is necessary to extend the twisted-pair network over fibre technology to connect with surveillance cameras and transfer video signals back to the network for security monitoring.

Media converters and wireless gateways based on LTE/5G cellular technology ensure the PCS and EMS remain connected to battery assets, helping to deliver peak shaving, frequency regulation and energy management. As a point of note, peak shaving helps flatten demand peaks and avoid peak demand charges.

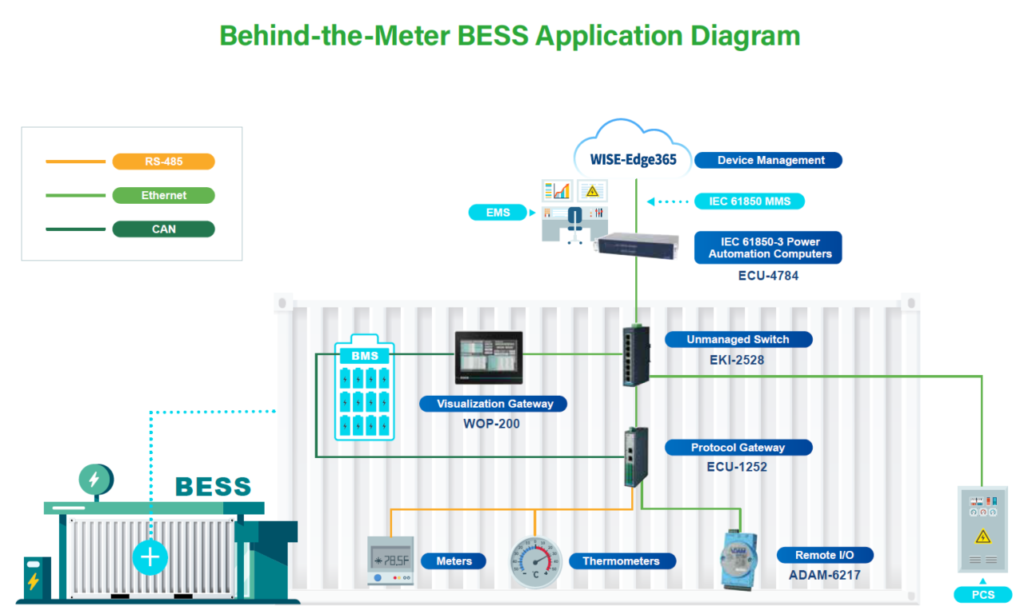

Equally, for behind-meter (commercial building/home) BESS applications, the optimal selection of I/O modules, protocol gateways, Ethernet switches and substation-grade (IEC 61850-3) automation computers will support the device bus protocols required in the architecture.

In a typical compact behind-meter BESS set-up, Ethernet I/O will serve to collect HVAC data, including temperature changes. This data will connect to a gateway that employs a CAN bus interface to convert BMS data to Ethernet networks. A visualisation gateway can act as a human-machine interface (HMI), facilitating the efficient visualisation of BESS data.

To establish connectivity, all machines can link to an eight-port unmanaged switch that subsequently transmits the acquired data to the EMS. An edge device management cloud service will enable the remote monitoring and management of devices across all behind-meter BESS installations, ensuring complete micro-grid performance and visibility.

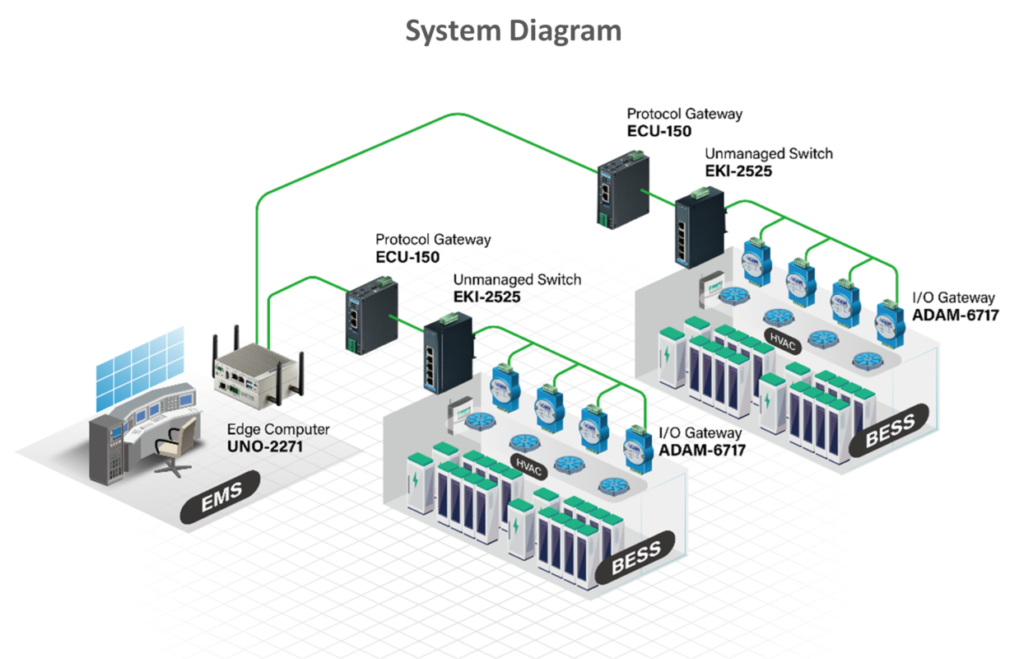

The stable operation of BESS is also reliant on the identification and adoption of optimal remote I/O gateways and edge computers. These devices can effectively monitor BMS, EMS and ECS conditions to ensure the safety of BESS, while industrial switches, routers and protocol gateways provide robust network infrastructure with VPN and IT protocols for enhanced data security.

Potential gains

To highlight the potential gains available from creating a connected IoT infrastructure for BESS efficiency, balanced energy utilisation and better energy security, consider the following real-life example involving HVAC control. HVAC control in BESS requires I/O signals such as analogue inputs for temperature data acquisition in the battery rack, and digital output for alarm detection. In addition, edge gateways are necessary to deal with data processing and control, while edge computers provide overall system management.

This particular solution sees each battery rack feature a single I/O gateway as the HVAC controller. Notably, these I/O gateways contain I/O modules and basic computing functions to deal with the I/O control process and alarm/event handling. Each battery bank (comprising several battery racks) takes advantage of edge gateways to manage devices (including the I/O gateways) and transmit data to the edge computers. In turn, these edge computers run the management systems that monitor the equipment status of each battery bank. An unmanaged switch connects the Ethernet devices.

The benefits of this solution are many. Firstly, it allows the completion of key energy management tasks and maximises solar power output. Furthermore, the use of a web-based platform provides immediate access to data.

Edge-to-cloud solution

In another real-world use case, an energy storage technology company wanted to build an IoT-ready BESS with an edge-to-cloud solution for its client, a metal extraction and refining plant. The IoT-based solution facilitates BESS monitoring and control for the efficient use of electricity at the plant.

Among the main requirements were an IoT gateway or edge controller with high density I/O points for this large-scale BESS and the implementation of IoT network infrastructure for remote monitoring. The system integrator (SI) developed an energy storage management system to monitor and control the energy facilities at the customer’s plant, using an EtherCAT automation controller with CODESYS as the edge controller and main data gateway.

In this case, the automation controller collects status data from the subsystems, converts the data into a unified format for processing with SI-developed algorithms, implements subsystem control such as battery charging or discharging, and uploads filtered data to the local server and the cloud SCADA system.

The SI chose this particular automation controller because it is a high-density and flexible computing system that can easily expand to over 20,000 I/O points for larger scale BESS deployment in the future. In addition, the EtherCAT controller supports the CODESYS programming environment and can run on both Linux and Windows operating systems, making it very convenient for the SI to develop domain-specific applications.

Another industrial PC takes care of video streaming from the plant’s surveillance system. Here, a Modbus RS-485 remote I/O unit acts as the access control system, which not only collects and transmits data from devices at an access point but also receives commands from the controller to open or lock the door.

The success of the project hinged on field-proven ruggedness: the metal extraction and refining plant and its power generation and energy storage facilities exemplify the harshest environmental conditions prone to dust, shock, vibration, high temperatures and electromagnetic interference. Hardware units with wide temperature support, high EMC capability and other rugged designs are proving their reliability in this project.

Another key factor was openness and scalability: the operator expects its energy system to continue growing, whether in the public cloud or on-premise. The open standard cloud platform made it easy to develop a highly scalable system and migrate systems across platforms and clouds.

The future is connected

Companies around the world are facing the challenges of rising energy prices and a pressing environmental agenda that calls for cleaner energy use. An increasing number are therefore building – or considering building – on-site power generation systems and BESS. A reliable Industrial IoT framework is part of the critical infrastructure that enables effective BESS management and the digital transformation of energy practices.

The IoT collects and communicates real-time data, giving BESS asset managers unparalleled visibility into devices and operations. It exchanges data to assist with asset monitoring, metering measurement, equipment maintenance, performance optimisation, demand and capacity management, and the identification of cost-saving opportunities.

About the author

Paul O’Shaughnessy serves as both the Industrial IoT Sales Director for Northern Europe and the Energy & Utilities Sector Head at Advantech, a provider of IoT intelligent systems and embedded platforms which manufactures its own hardware and software. The company offers a full turnkey design service to provide customers with an all-in-one control and communication solution for fully integrated BESS control and management.

Tyler Fields is your internet guru, delving into the latest trends, developments, and issues shaping the online world. With a focus on internet culture, cybersecurity, and emerging technologies, Tyler keeps readers informed about the dynamic landscape of the internet and its impact on our digital lives.